Available

Available

| Product Name | OEM Customized Aluminum Alloy Precision Die Casting Car Parts |

| Manufacturing Process |

Mold: Mold Design, Mold Base and Steel, Milling & Drilling, Heat Treatment, CNC Cavity and Core, CNC Electrode, Wire cutting, EDM, Polishing, Mold Assembling, Mold Trial, Etc. Product: Die Casting, Deburring, Punching, Polishing, Grinding, CNC Machining, Drilling, Tapping, Cleaning, Surface Treatment, Inspection, Packing, Etc. |

| Applied Software | STP, PRO/E, Auto CAD, Solid Works, UG, IGS, CAD/CAM/CAE |

| Material |

Aluminum (ADC12, A380, A360, Etc.) Zinc (Zinc#3, Zinc# 5, Zinc# 8, Etc.) |

| Surface Treatment |

Anodizing, Powder Coating, Painting, Electroplate, PVD, Sandblasting, Polishing, Laser Engraving etc. |

| Tolerance Precision | Can Also be Customized; Or +/0.02mm, |

| Dimension | As Per Customers Request |

| Part Color | Silver, Black, Red, Blue, Gold, Oliver, White & etc. |

| Free Samples | Can be Discussed |

| Quality System | Inspection During Process and 100% Inspection Before Shipment |

| Lead Time | Based on the Quantity of Order (Usually 25-35 Days) |

| Packing Method | Plastic tray, Bubble Bag, Customized Packing, Etc. |

| Shipping | By Sea, By air, By DHL, UPS, TNT & etc. |

| Certification | All products SGS,CTI and RoHs approved, All material REACH approved |

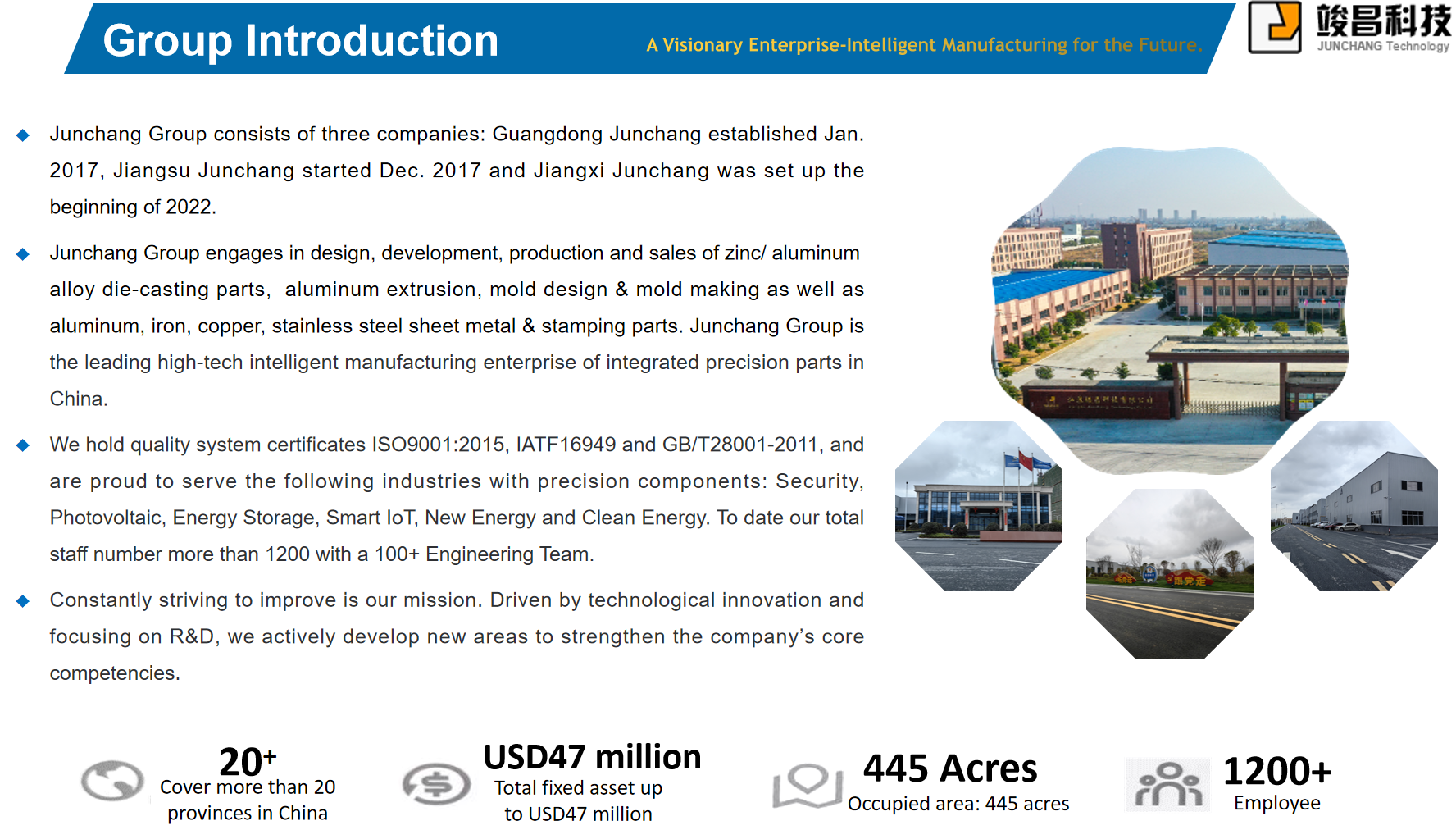

Company Introduction: